Desiccant Dryer System

While we recommend the use of Nitrogen to pressurize all composite bond autoclaves. Some facilities running lower temperatures, under 400F, use shop air or dedicated compressors to pressurize their autoclaves to reduce run cost and initial installation costs. If you are the composite shop that is pressurizing an autoclave with a compressor, you NEED a dryer to remove the moisture from the air. The moisture will ultimately damage the entire autoclave including the electronics that are connected to the autoclave.

THE FOLLOWING AUTOCLAVE COMPONENTS THAT ARE MOST AT RISK:

- Cooling coils

- Heating Elements

- Vacuum Transducers

- Gauges

- Insulation

- Etc…

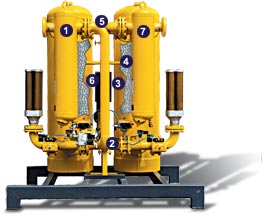

Desiccant Dryers: HOW THEY WORK

The pre-filter removes solid particles (> 0.01 µm) and oil residue from the air that is to be dried. The air then flows through the inlet valve and lower diffuser into one of the two desiccant tanks. The desiccant traps the moisture, leaving the dried compressed air to exit the desiccant tank via the upper diffuser. The main flow of dried compressed air then finally reaches the compressed air network via a check valve and the downstream dust filter. A small portion of the dried compressed air is drawn off as purge air via a control valve and alternately regenerates the desiccant in whichever tank is not in use.

- Pre-filter

- Inlet valve

- Desiccant tank

- Desiccant

- Check valve, Regulating valve (not visible)

- Desiccant tank

- Dust filter